Torus Pak®: Disrupting the Meal Value Chain

For eons the only way to prepare a meal was to gather the ingredients, cook the meal, and serve it up. Our caveman ancestors didn’t have the option of swinging by the market on the way home to pick up supper, or making dinner reservations at a posh restaurant.

As society grew and developed, so did the need for meal preparation on a larger scale. We took up agriculture and began to mass produce ingredients, but we still had limited options as far as serving meals. Prior to the invention of the Torus Pak® packaging solution, the meal value chain led down one of two paths.

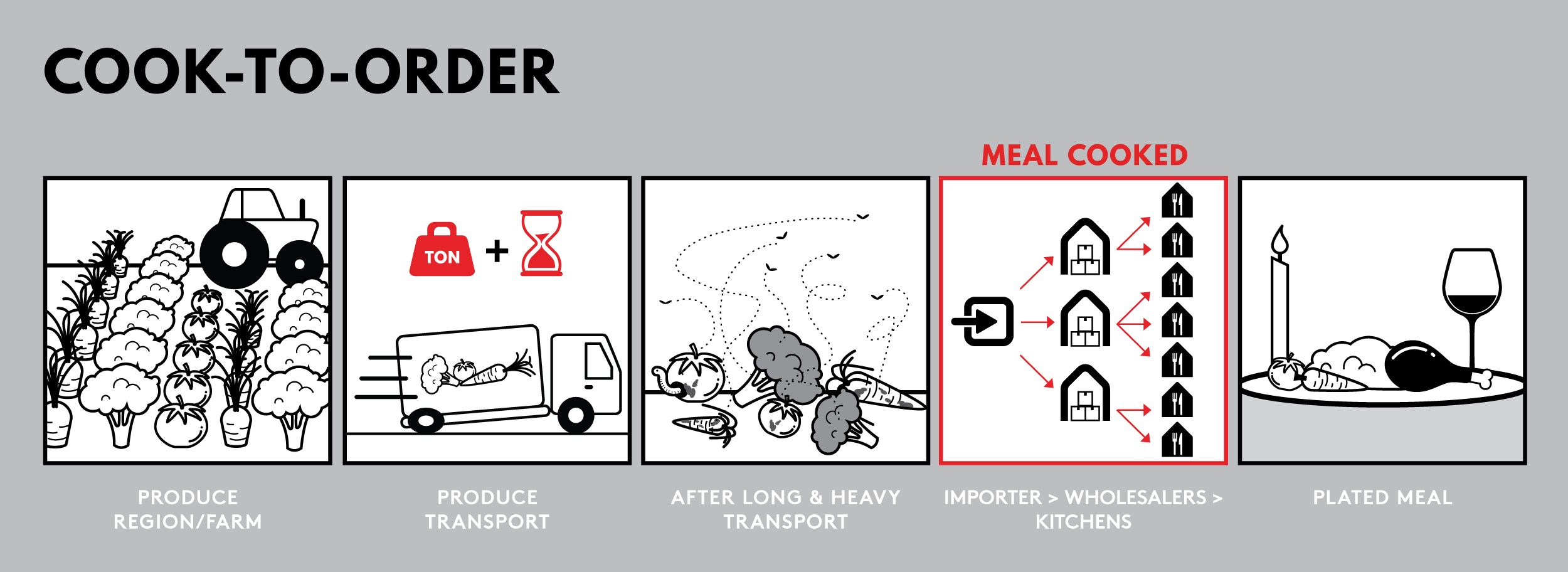

Path 1: Cook-to-Order

The most obvious method that arose was to transport massive amounts of raw ingredients to a site where people gather and then cook each person’s meal to order. It’s exactly what was always done, only on a larger scale. Instead of lighting a fire, we could fire up the ovens – and instead of preparing a meal for one person or a few, we could serve hundreds of people at a single site.

Each meal could be pleasantly plated, however foodservice providers had to deal with wastage of goods that were damaged or spoiled during transport over long distances, spoilage from ordering ingredients that were not all used before expiring, high costs of a fully equipped kitchen and professional chef, and a lot of time to prepare each meal individually. So it was an inefficient route.

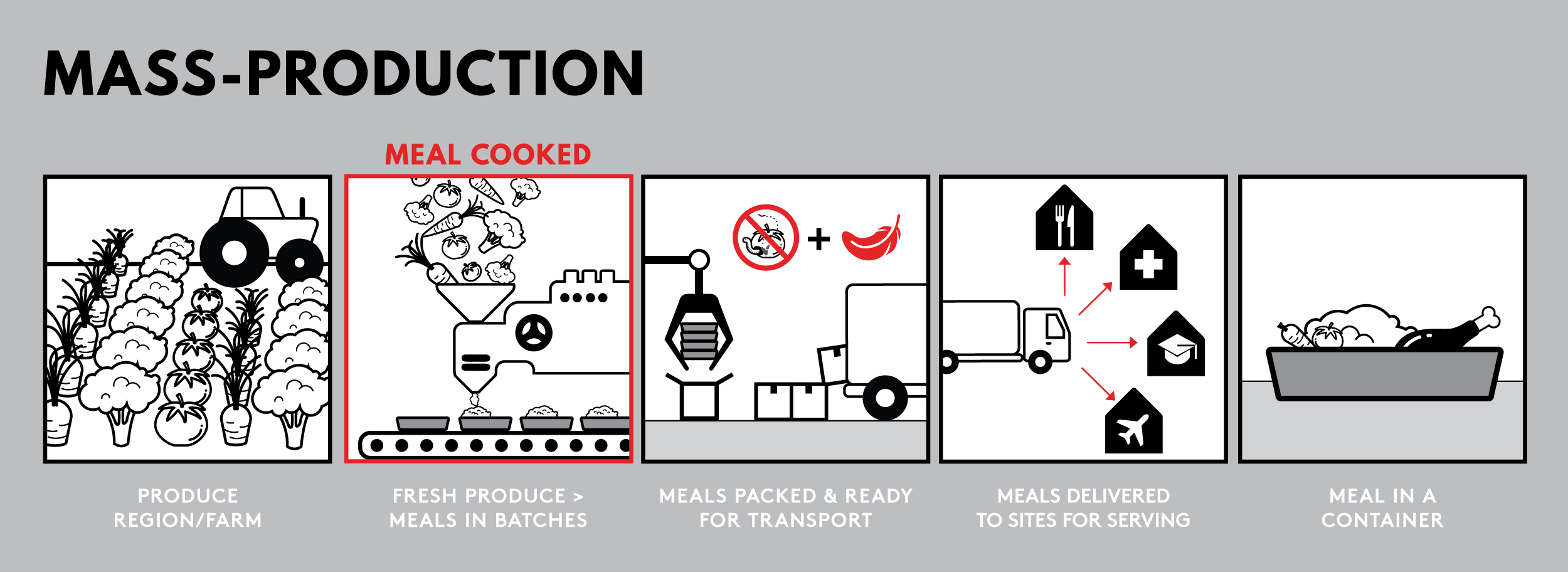

Path 2: Mass Production

With the dawn of the industrial age, we developed the ability to produce all kinds of things on an even larger scale. We could can or freeze raw goods to improve transportation efficiency and increase the shelf life, and innovative technological improvements allowed us to serve more and more people at a single site.

Thus another option for the meal value chain became available: mass production. This new path involved producing meals in large batches which were then packaged for delivery to foodservice providers. This method increased efficiency in four key ways:

- eliminating spoilage that occurs during the transportation of raw goods

- dramatically increasing the shelf life of food

- limiting plate waste through pre-portioning meals

- reducing the expense of having a fully equipped kitchen, chef, and other professionally trained staff members

So it was a much more efficient solution, however the customer was forced to eat the meal straight out of the container. The only other option was to flip the container over to scrape the food out onto a plate, which resulted in a distorted and unappealing presentation.

Why does the presentation matter?

If you’re sitting at home alone one night and decide to enjoy a TV dinner, you may not care whether you eat it out of the container or on a plate. But presentation makes a big difference for people who will be eating the meals day after day in places like schools, care homes, hospitals and correctional facilities. And many foodservice providers, such as hotels and restaurants, prize a gourmet presentation of their meals.

The solution’s beginnings

One method that attempts to reconcile the meal value chain dichotomy involves transporting frozen components instead of raw goods, which are then assembled into meals by a chef in a kitchen. But as it is only a partial solution it provides only partial benefits.

International research conducted by the technology company Winnow shows that over 70% of food waste happens before it even reaches the consumer plate. Raw goods have to travel a long way en route from the farm to the distributor and the kitchen. They often spoil, get bumped and smashed, or become otherwise unusable by the time they arrive at their destination. By transporting the same goods frozen, however, they are protected both from spoilage and damage due to shifting.

Thus transporting frozen components does reduce food wastage during transportation while allowing a plated presentation of the meal, however it still requires a professional chef to assemble the ingredients into a (typically overportioned) meal in a fully equipped kitchen.

Why are we forced to choose between efficiency and customer satisfaction?

The trouble is that gravity says you can’t get the meal out of the top of the packaging properly; you have to eat out of the container. That tends to feel a bit like being forced to eat out of the dog’s bowl. You could always flip the container over and scrape the food out onto a plate, but that still yields an unappealing presentation. But what else are we supposed to do, since gravity holds the food down?

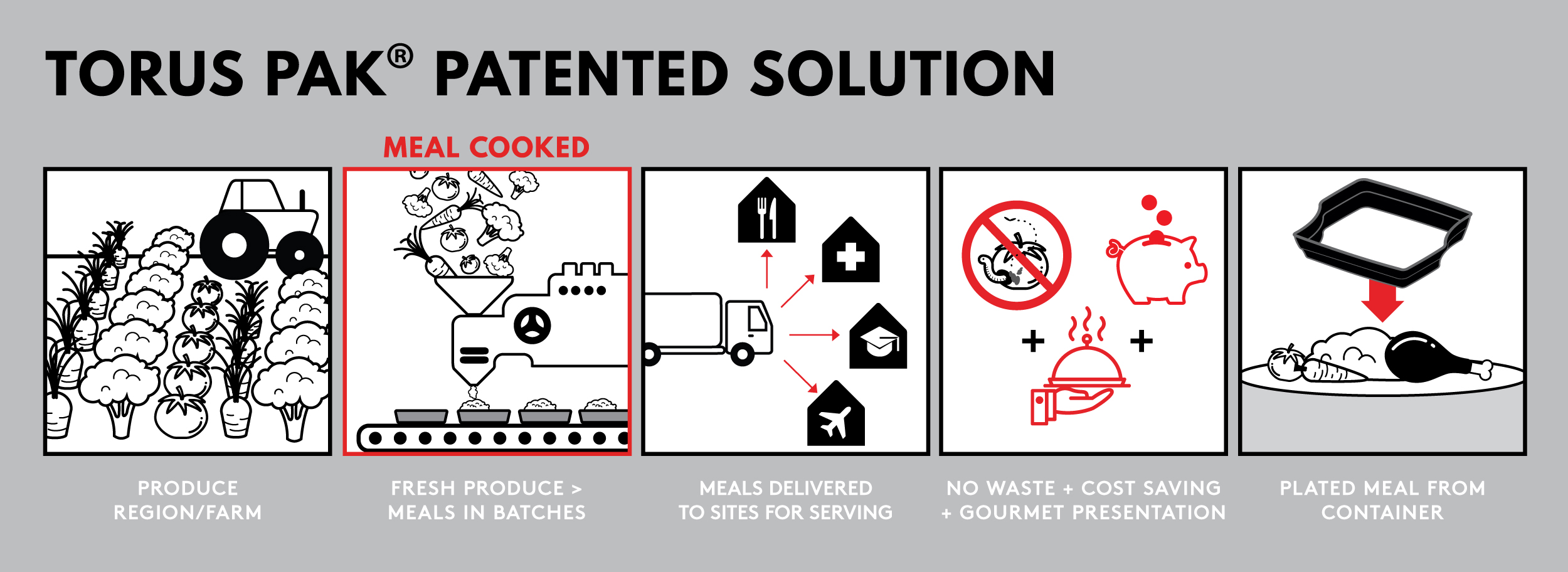

Torus Pak® provides a best of both worlds solution!

Torus Pak® blends the efficiency of the mass production path with the plated presentation of the cook-to-order path: it’s the ultimate solution to merging the meal value chain paths!

How is it done? Meals are produced in large batches and then packaged individually. The elegant solution that allows a plated meal result is to simply get the meal out of the bottom of the container instead of the top!

Click here to watch a video demonstration

Instead of eating out of a container, Torus Pak’s patented technology allows you to place the packaged meal on a plate, remove the film from underneath the meal, and take the packaging away for a beautifully plated presentation.

How Torus Pak® creates a NEW value chain

Torus Pak® provides a solution which disrupts the long established meal value chain dichotomy by melding them in a way that allows the benefits of each – the efficiency and cost savings of mass production but also the presentation of a gourmet plated meal.

A more environmentally friendly solution

A study by the Royal Swedish Academy of Science found that the three main food preparation methods (frozen, semi-prepared and homemade from scratch) “showed relatively similar environmental impacts.” But there’s more to the story – while the environmental impacts of preparing the food via different methods were similar, the environmental impacts of reducing food waste sharply tips the scales in favor of frozen ready meals.

Heidelberg University Hospital put this to the test and found that in switching from cooking on site to using frozen ready meals, 30% less food was used to get the same output on the plate. Thus if the environmental impact of preparation is similar but you have 30% less food to prepare to get the same result, you’ve found a method that is 30% more efficient!

Reducing food waste in itself is a worthy goal. According to the Food and Agriculture Organization of the United Nations, “Per capita waste by consumers is between 95-115 kg a year in Europe and North America.” With so much food waste, we’re throwing away nearly €900 billion worth of food each year.

By creating a way to reduce that waste, Torus Pak® facilitates not only a monetary savings but also helps lessen the negative impact to the environment. Contrary to what many believe, food waste does NOT readily decompose in landfills. The process of decomposition requires air, and when the waste is all piled up in plastic bags and packed tightly together, the air can’t reach it.

What’s worse, since the organics can’t decompose they release methane – a much more powerful greenhouse gas than carbon dioxide. Considering that consumers in the US and EU waste approximately 1.3 billion tonnes of food each year, the impact adds up!

Torus Pak® steps in to prevent this by creating a better path.

Step 1: Prepare meals on a large scale in efficient batches.

Step 2: Portion and package these meals using Torus Pak® patented technology.

Step 3: Blast freeze for preservation and transportation.

Step 4: Deliver to foodservice provider for plated presentation to customers.

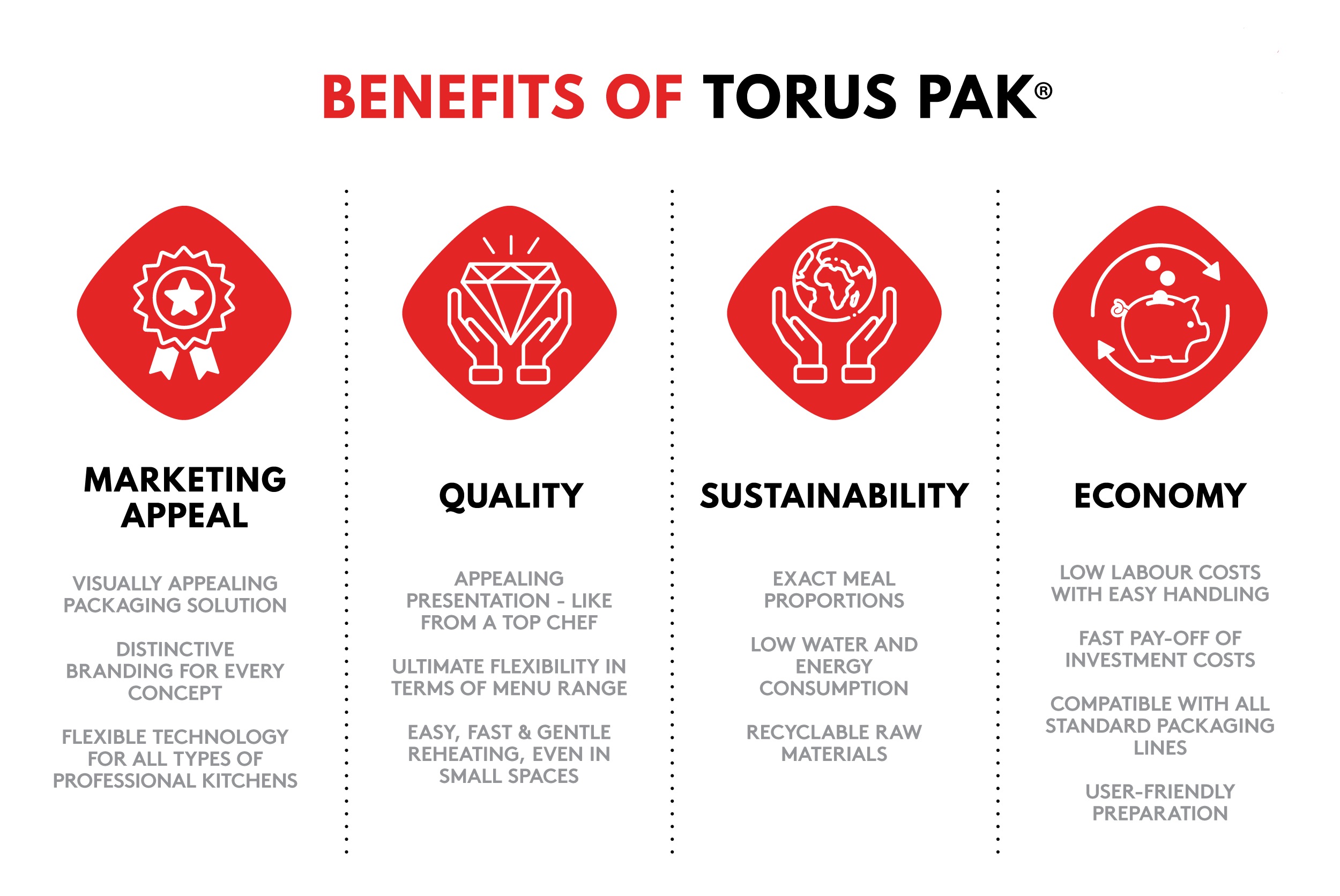

A truly disruptive technology

Torus Pak® is a patented packaging technology that has enabled the food industry to redesign its value chain by significantly improving efficiency and generating a more cost effective solution – all while maintaining the high-quality presentation and home cooked feeling of a delicious, gourmet plated meal!

_____________________

For further enquiries, contact us at europe@toruspak.com

For the latest updates on Torus Pak®, follow us on LinkedIn

News, press & videos

News, press & videos