Why TorusPak®?

A patented bottom‑release tray system that helps food‑service teams plate faster, cleaner, and more consistently—while meeting the controls and documentation that serious buyers expect.

Benefits at a Glance

Built for high standards—across two high‑pressure environments

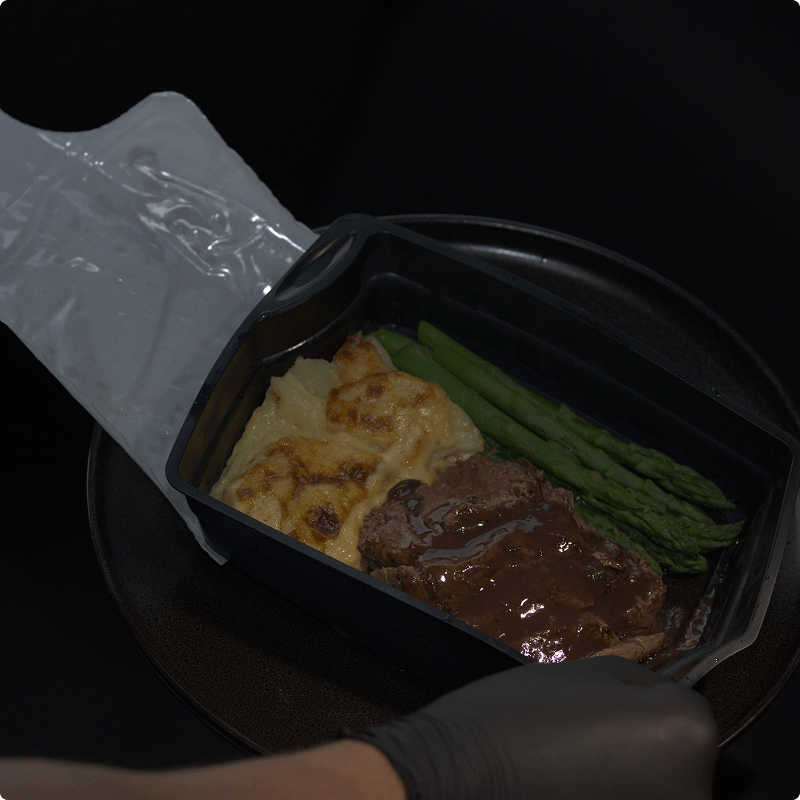

Plates perfectly

Food looks exactly as the chef intended—neat, appetising, and ready to serve.

Flexible

Fits seamlessly into existing packaging lines and works for various meal types.

Seamless preservation

Keeps food fresh and safe, extending shelf life without compromising quality.

Sustainable choice

Designed to support lower overall impact by reducing food waste and rework—using materials selected for demanding food‑service performance and recycling compatibility where facilities exist.

How it works

Tray to plate—cleanly and consistently.

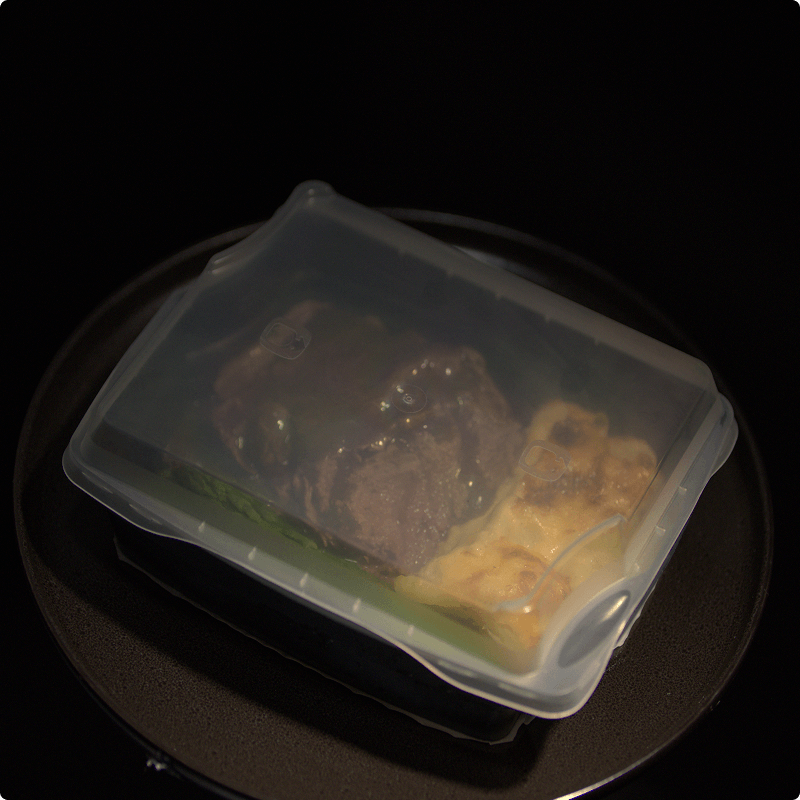

Seal and chill/freeze as usual

Re‑thermalise according to your service model

Open and release the meal onto a plate using the bottom‑release mechanism

Serve with confidence—clean release, consistent presentation, smoother service.

TorusPak® is designed to integrate into established ready‑meal operations. If you share your current tray size, sealing method, and regeneration process, we can recommend the optimal configuration.

Designed to Adapt

Fits your line

TorusPak® integrates with standard sealing systems—so you can adopt tray‑to‑plate presentation without redesigning your line.

Flexible options

Choose round, square, or rectangular formats to suit your menu—without compromising the plated result.

Seamless preservation

Supports gas flushing and vacuum packaging to ensure extended freshness and meal quality.

Scalable solutions

From retail to catering, TorusPak scales to meet volume demands efficiently.

Frequently Asked Questions

Quick answers to common questions about implementing TorusPak®.

Implementation is typically straightforward. We align tray format, sealing method, and service workflow, then provide training guidance for consistent use.

Yes. We recommend a sample or pilot to confirm plating results, sealing performance, and re‑thermalisation behaviour with your recipes.

Yes. We support customers globally and can advise on logistics, lead times, and documentation by destination market.

Engineered to Perform (Tray 5110)

- Dimensions (exterior): 196 x 156 x 40 mm

- Material: Food-grade PP (polypropylene) copolymer

- Temperature resistance: −40°C to +121°C (suitable for microwave, convection ovens, and steamers)

- Closure options: Click lid 7101 or sealing film (for high-volume operations)

- Documentation: datasheets and compliance packs are available on request(europe@toruspak.com)

Want to see the difference on a plate?

Learn how our innovative packaging solution can elevate your food service operations.

Request samples Book a demo Talk to an expert